Making Business Decisions that Consider our Earth,

Community, and Health from the Beginning

Bike Friday was created by Green Gear Cycling, Inc. We have been committed from the beginning (1992) to making environmentally benign decisions in our choices of the products we make, the materials we use and the processes with which we manufacture.

Bike Friday was born out of a love of cycling. We ride for many reasons. To exercise our human power to live a good life, to stay connected to the basics of living healthy. We also ride for the fun freedom of flying quietly on the wind, filling our lungs with clean, fresh air, with low impact on the world we live in.

We named ourselves Green Gear Cycling Inc. to remind us that we have a choice of how we use resources, in the decisions on what we produce and how we sell. It has helped us keep a small footprint, a very important attribute if you are trying not to step on the flowers.

Manufacturers are often associated with pollution and waste. Putting economic desires over the good of the communities in which they reside. Polluting the air and water, but more astoundingly, poisoning the people who work for them and buy from them. What happens to the generations that come after us? What kind of world will they inherit? I have 3 daughters and I ask myself this often. I’ve always felt that our actions should consider future generations, but now there is a sense of urgency that has suddenly become personal. We have seen the degradation of our region in our lifetime.

Green Gear/Bike Friday is trying to do its part to be a solution instead of part of the problem. We have made many choices over the years that could have had many different results if we didn’t consciously decide on the benign.

Here is a short list of past projects in which the decision to reduce waste and toxicity were consciously made:

Just in Time manufacturing. “JIT” has been lauded as a production system that increases quality and reduces waste. What you don’t hear too often is that it is a more benign production process than batch production from forcasting. If applied properly, JIT attacks waste on all levels and includes the people that work within the system to identify where waste occurs. Waste in all its forms. From poor ergonomics to what gets recycled and the system that handles the materials. Anything that goes to the landfill is a potential revenue source and is viewed as waste. The ultimate goal in JIT is to have full cycle manufacturing where nothing exit’s the production stream other than the desired product.

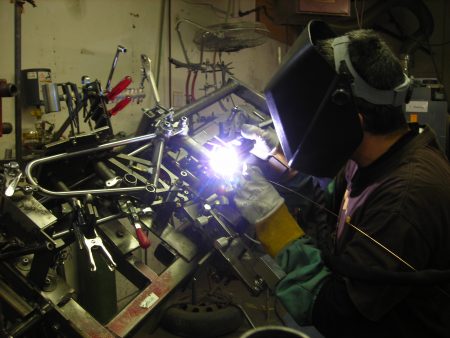

Chromoly Steel Frames. We chose to build our bikes primarily out of Chromoly Steel for several reasons. Steel is quite light for its strength and easy to work with. We are able to make 16 lb folding road bikes, quite light! We expect our bikes to be ridden long distances all around

the world and steel is the simplest material to repair with common tools found around the globe. If a water buffalo stampede tramples your bike we want it to be possible for a local farmer to patch it up so you can get back on the road for your adventure.

Metal Preparation Using Sand Blasting and No Chemicals. Most bikes are still made of metal of some sort. Metals are often prepared for painting by using acid etching chemicals. These are used to both clean the surface and to prevent the surface from flash rusting while it is sitting around waiting to be painted. Green Gear learned early on that these chemicals were not good for our employees or the environment. They consume large amounts of water in the buffering process that deals with waste before they are flushed into the

sewer system (yes, flushed into the sewer system).

What we discovered with our JIT production system, which deals with each bike individually (not in batches), was that the bikes don’t sit around in the air long enough to flash rust. Now each Bike Friday get fully sandblasted and immediately coated. Blasting provides a cleaner surface with a rough texture that holds the powder coating better and doesn’t put the operator at risk, and we don’t need the thousands of gallons of tainted water that would enter our waterways if we used chemical etching. A Win Win Win all around.

Powder Coating. We adopted Powder Coating at the very beginning of the company in 1992. This was at a time that Imron spray paint was the bicycle finish of choice. However, we knew that automotive quality spray paints were full of organic poisons. The waste liquids and vapors have to go somewhere and a lot of them cannot be controlled. The real cost of that kind of activity is never fully understood. We wanted to be good neighbors and conscientious employers.

* Powder coating is a highly durable coating

with an excellent finish. It has near zero volatiles and the waste can be baked into a block and is inert enough to be put in the landfill. (We are trying to find a use for it though so it doesn’t go into the landfill.)

Bike Friday’s Pre-loved Bike Program. How about a system that kept bikes running long after most other bikes had been relegated to permanent storage or the dump. That’s the beauty of the Bike Friday Certified Pre-loved bike program. It is modeled after the European concept that companies should be responsible for the products they put out to the public throughout the products full life cycle.

Our pre-loved program does that and more. From what we can tell, Bike Fridays have the highest resale value of any bike on earth. Our customers like quality and innovative bikes and Bike Friday is happy to deliver them. But what happens to the old bike when a customer decides to upgrade? Does it sit slowly rotting away in the garage like many bikes? Is it sold at fire-sale prices? No, Bike Friday gives an equally beneficial portion of their original purchase price back to the customer when they trade up. Instead of disposing of the bikes, we refurbish them, give a near to new warranty and offer them at a reasonable price to someone who may not be able to afford the latest models.

When a bike comes back that is just too worn, we part out the good stuff and recycle the bad stuff. About the only thing that still goes to the dump are the tires and old saddles.

Eugene’s Toxic Right to Know. This is probably the strictest toxic material reporting law in the country. Even though Green Gear/Bike Friday has continued to grow, our programs to reduce waste and toxins in our system have kept us well below the required reporting level. This is where we want to stay.

Where do we go from here? Green Gear Cycling has plans for the future. We will continue to banish waste wherever it is found.

You have our commitment to the future.

Alan Scholz

Bike Friday Co-founder

Hanna Scholz

Alan’s oldest daughter and Bike Friday President

Vision of the future:

Reduce reliance on car culture through personal transportation solutions that support healthy modern lifestyles and sustainable communities one great bike at a time.

The mission of the company:

Be a company with a conscience offering elegant transportation solutions for modern world problems. Passionately build high quality, versatile bicycles, personalized to empower people, with freedom and convenience, to ride anywhere on a bike that fits them.

GUIDING PRINCIPLES AND BELIEFS WE USE AT GREEN GEAR CYCLING IN OUR BUSINESS (GREEN GEAR CYCLING, INC., IS OUR INCORPORATED NAME. BIKE FRIDAY IS OUR BRAND NAME.)

Our guiding principles and beliefs are reminders to action.

– We serve at the pleasure of our customers.

– Our cause is furthered through our service to our customers and our relationships with the Bike Friday Community.

– We believe in a community as “things we do and share because we care for others, and for the good of the place” (our world). A non-monetary exchange of value.

– We try to do unto others as they would be done onto.

– We are human, and as humans, we are prone to fallibility … this is inescapable. If something should go wrong in the process we will do our best, at our best speed, to make the situation right.

– We will not let policy get in the way of good service.

– To serve is one of the requirements of a complete and fulfilling life.

– We believe an important part of Life is doing Meaningful Work.

– We believe in trying to integrate our life, beliefs, and interests with our work.

– Good work is about supplying service, not stuff. It’s about making long-term relationships with customers, not just transactions with numbers.

– Building to order and selling directly gives us connections to the users of our work.

– We understand good customers will tell us how to deliver good work if we listen.

– Bike Friday is a concept.

– The bicycle is one of the best inventions created by humans. We love bicycles.

– Human scale, health enhancing, highly social, low global impact, extremely economical, low maintenance, understandable, approachable, friendly and in this fast modern world, bicycles are still the most efficient transportation ever designed.

– A bicycle can and should be integrated into most people’s lives because of the health, social, environmental and economic benefits it supplies.

– A bicycle amplifies you as a person. It boosts self-esteem. It makes you more capable, stronger, more outgoing, and healthier, but it must be there when you need it wherever you are in the world. That is Bike Friday.

– We believe that example teaches best. As cyclists, we are all ambassadors.

– We have seen that if we want to be welcome and have a low impact, then traveling by bicycle is a great way to respect the people and places we visit.

– Arriving by bicycle is one of the best passports in the world for meeting new, interesting friends and breaking down some of the world’s perceptual borders.

– We strongly believe that a bicycle culture is a healthy culture and therefore the presence of bicycles or lack thereof, makes it a good ecological and social indicator of the health of a city or country.

AS DESIGNERS, ENGINEERS, AND BUSINESS PEOPLE WE BELIEVE

Before meaningful work can begin we must take responsibility for ourselves.

We must not blame others but be proactive, using our developing self-awareness, imagination, and conscience to direct our independent will.

Constant incremental improvement is needed from everyone, not just a few.

A feel for materials is necessary for design. That means making stuff with our hands. We believe we should strive to learn the skills to become hands-on philosopher mechanics.

Adding to Life requires experimentation, flexibility, collaboration, and speed.

The bicycle is an important mechanical solution to modern man’s environs and therefore requires — and deserves — our best continuing efforts as designers to integrate it for the pleasure and the specific needs of each individual’s lifestyle.

We know that all prototypes do not work as expected. The good ideas pay for the rest. You can’t tell in advance if ideas work or which are the good ones. So don’t hesitate to try new ideas. If it is the first time, then it can’t be wrong. There can be no wrong for creating the first of something. So do it right the second time. Do it fast the first time. Make a lot of attempts. Test things yourself, then get promising designs to Beta with users who can tell you their real worth.

We believe customers are the main purpose of a company. Much of business, and design especially is done backward, with, it seems to us, the customer’s input last. We’re not Vulcans but we think that is illogical. Beta with customers, listen to users. Do what they want.

We believe in not re-inventing the wheel, but trying to build on the shoulders of the giants before. To read, study, listen, share, test, and record.

—The Scholz Brothers Hanz and Alan Bike Friday/Green Gear Co-founders

We want to remember and thank our father, Earl W. Scholz, and mother, Mary Esther for helping us, allowing and supplying the environment for us, to choose our calling. Many people in the western world are missing the generation in front of them that would have taught them how to cycle. One of our responsibilities is to teach our children and our friends about the freedom and health that being “Human Powered” brings.